BINNEKRING BLOG

AfterBurn Report 2018: Sanitation

Words & Photos: Lara ‘Squeaky Queen’ Warren

Burning Seed, Sanitation Services – Team Lead

AfrikaBurn, WASH (Toilets) – Co-Lead

Within a few minutes of landing in South Africa, I started to realise the effects ‘Day Zero’ could have. Cape Town was on strict water restrictions of 50 litres per person, per day. Dam levels were critically low. The public toilets in the airport had all but one tap turned off, with hand sanitiser in the place of soap. Toilets had large posters advertising to please keep showers short and not flush toilets unless necessary. Over the PA a recording stated the dire nature of the water shortage and encouraged all guests of the city to observe the strict water restrictions.

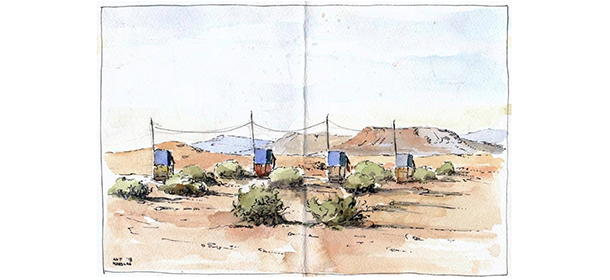

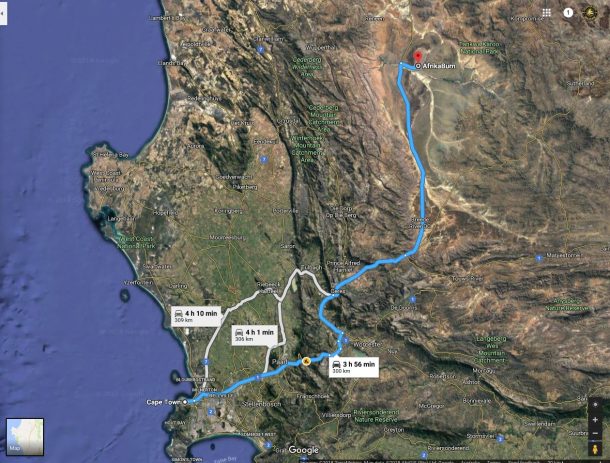

It felt like I was entering another world, even though I’d experienced living on tank water and had grown up in the desert in Australia. I had come over here to help roll out a new toilet system for the largest burn I’d ever been to. Afrikaburn, with its ~11,000 attendees, would begin in less than one month in the Tankwa Karoo. A dry, flat, windy desert, approximately 4 hours drive from Cape Town, on the same latitude as the town I grew up in, Broken Hill, Australia.

Previously the loo crew had implemented pit toilets, with supplemented portaloos. But the size of the event, the environmental impact and last years flash flooding had all signaled a need for change. I heard reports from previous Department of Public Works (DPW) crew that outbreaks of gastro and “bos kaks” (bush poos) were all too common. The need for a better system was born and plans were well afoot when I arrived.

I met with the Loo Queen of AfrikaBurn, Cara. With her cheeky grin and can do attitude, we headed to Cape Town’s waterfront to the birthplace of the newly designed ‘Loos with Views’.

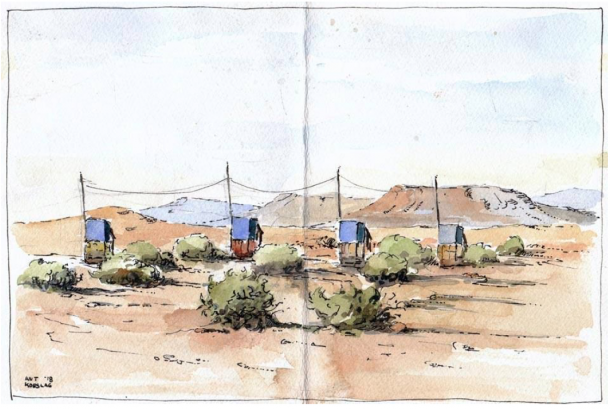

With 20 years experience in the portable toilet industry and ethos of providing innovative and creative products with care towards the environment, the sanitation engineer that designed the new Thrones (who is a longstanding member of the AfrikaBurn community) seemed like a good partner to involve. His idea was to create a new loo with a view that was portable, used recycled materials, and employed eco-friendly enzyme-based odour control. The system had been trialled at the Origin Festival, with great success just a few months before. The only thing left to do? Roll it out to the Tankwa. We talked logistics and arrival dates of the flat packed loos and headed back to The Yard to pack the rest of the gear.

It was a cold and dark morning on the first of April, as we sat waiting for the overlanders to arrive and transport us from the bustling Cape Town, out along the treacherous R355, to the home of AfrikaBurn. With a planned stopover for lunch in Ceres and a quick stop at the Tankwa Padstal, we arrived into the blistering heat of the Tankwa Karoo in the early afternoon.

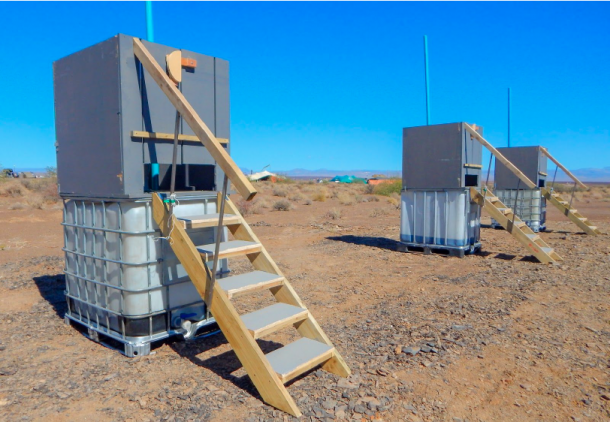

I knew this was going to be a steep learning curve as I felt the expanse envelop me. So far away from basic services, so little infrastructure. The loos with views were to utilise flow bins, also known as 1000-litre Intermediate Bulk Containers (IBC’s), for the liquid waste hold. Because of the water situation in the Western Cape, getting hold of these resources proved difficult and the supply of sufficient IBC’s was affected. Everything has a trickle on effect.

The Loo Crew found themselves significantly short of the required number of planned waste hold containers, with no viable way to procure more before the event started in just a few short weeks.

The plan was to have 192 Throne units and 48 Urinal units for this year’s event. But with the shortfalls of IBC supply, we could only construct approximately 150 units. It was decided the urinals could be done without this year and we could spread the rest of the units around to sufficiently supply the event’s patrons. Each unit was designed to have the capacity to hold the daily output of 600 people for 24 hours. With the event expected to host around 11,000 people this year, and running for seven days, we would have just enough capacity, plenty if we could pump out some during the event.

Construction started and with only a few minor hiccups (to be expected with a new design) we were well on our way to having all the components made ready for final placement and assembly.

Placement of the loos was based on previous years high use areas and areas where bos kaks were prolific. But this year was to see the Great Switcheroo, where the Loud Zone was moved to the other side of the Binnekring. For further information on the placement of the toilets, see this map. A few teething difficulties surfaced once people began to fill the space. The new Loud Zone had a large number of campers and was a high use area. We supplemented as best we could by forklifting units from lower use areas, to areas of high use. Unfortunately, the soft sand and access through river beds around the Loud Zone, made the majority of this area inaccessible to our forklift.

If we’d had the correct amount of flow bins (IBC’s) delivered, as ordered, we could have built new units in the areas of high demand as required. The units themselves are a simple construction. Made from recycled fruit bins and other recycled and repurposed materials. The units are standalone and can be forked even when full. Each unit starts with 200 litres of chemically treated liquid which provides a solid base. The chemical used is a combination of fruit oils and active enzymes. Initially it was thought the units would need to be tied down due to high wind and wobbling when in use, but they were more than sturdy enough without tying down.

A few minor issues arose once mass construction (~150 units) was under way. Nothing that the hardworking, and resourceful DPW Crew couldn’t handle and construction was completed ready for the next stage. After placement of the flow bins (IBC’s) was complete, the constructed boxes were lifted into position, secured and steps attached. Each unit had an LED night light attached to the handrail. These were wired up and linked to solar panels providing enough light to safely navigate the steps at night.

Sadly, some of the solar panels and LEDs were stolen from the banks of toilets along the northern side. Although care was taken to place them out of the way, high off the ground and secured with tech screws, I guess someone really needed them. From previous experience, the hand sanitiser was made less mobile and each cubicle was fitted with a hand sanitiser dispenser built into the rear wall (red panel in photo below). These worked well and no outbreaks of gastro were reported. Yay!

The problem of White Cobras remained this year. White Cobras are the often long, snaking pieces of fly-away toilet paper that sweep across the desert floor, creating a headache for the Loo Crew who diligently pick it all out of the spiky bushes. The clean toilet paper is provided in a 20-litre bucket with a lid to help keep bulk amounts of clean, dry paper for use. Inevitably, people leave the toilet paper on top of the bucket and when the wind whips up, it flies away. Some also thought this would be a good receptacle for rubbish and used tampons too, eww! Future plans are underway to create a better, bulk toilet paper distribution system for each cubicle. If you’ve got a good idea though, send it this way: [email protected]

As for pumpouts, the plan was to have a black waste removal truck, a honey sucker, transport waste from cubicles that were getting full, to the newly built ‘poo pond’ on a neighbouring farm. This is where the black waste is being turned into usable humanure for use on a neighbouring Tankwa farmer’s land. Alas, what arrived to pump out the toilets was insufficient equipment and the pumps kept getting clogged with various foreign objects. Remember – if it didn’t come outta your body, it doesn’t go into the potty!

I guess some people had bad luck and among the things dropped into the toilets included; a backpack, a wine bottle, set of car keys, drink bottles, beer bottles, many cans, hats, t-shirts and so many wet wipes. None of these things should be placed into the tanks on purpose, but I doubt these were all an accident. Some of these were able to be skillfully recovered by the amazing Loo Crew, but majority ended up clogging the pump truck.

With the pump truck broken and a replacement days away, we had to make do by shuffling around the lower use toilets that we could. Sadly this resulted in areas of high use having closed toilets and some participants resorting to bos kaks. Luckily these incidents were low and manageable. With the addition of the planned amount of cubicles and supply of a suitable honey sucker next year, these issues will easily be resolved.

Though the toilets on the whole, worked really well, for the full list of recommended improvements for next year, see the list at the end of this document. While we’re on the subject of improvements though, one main consideration for next year, that would be wise, is having fresh hands to help with toilet runs through the event. This responsibility has traditionally fallen on the DPW Crew that have been onsite for many weeks already and have worked so bloody hard in high wind and heat, from dusk till dawn, to get the city’s infrastructure ready to accommodate the massive influx of people.

This year, each and every morning, three teams of already tired DPW Crew set up a ute with trailers and equipment to spruce up the loos. We cleaned them, filled them with water when needed, sanitised them, refilled the toilet paper, cleaned up the bos kaks and collected all the MOOP and White Cobras. Each run would take at least 4 hours, each and every day. That doesn’t leave a lot of time or energy to enjoy this beautiful city with you.

In future (like Burning Seed has managed for the first time last year so successfully) I recommend a team of fresh volunteers be recruited to help with the toilet runs. The reward of a meal voucher for the DPW kitchen upon completion of a toilet run could be sufficient incentive. In my experience though, so many people just want to help, but don’t know how. This would be a fantastic way for many.

I thoroughly enjoyed working with the DPW Crew at AfrikaBurn, I learnt so much. I gained resilience, improved upon my forklift skills, made deep friendships and of course, gained first hand knowledge of an innovative solution to a difficult problem. With South Africa ranking at 133rd of 180 countries for access to clean water and sanitation, it’s no wonder basic services are a distant future for many. It excites me that people are thinking outside the box and creating a portable, recycled, affordable solution. It sure worked well out in the Tankwa. This is exactly the reason I continue to be involved with burns around the world.

Full List of Recommendations for future years:

1. Ensure a honey sucker is available to pump out cubicles that are getting full.

2. Purchase more flow bins and build the full amount of cubicles available.

3. Have a copy of the Material Safety Data Sheet for all the chemicals used in the toilets available. Give a copy of this to Medics in case of accidents.

4. Improve on night visibility by placing a light that’s visible from all sides of each cubicle.

5. Fit the area where the stairs meet the flow bin with a flat, stiff support (timber ply would work well). This would enable easier and safer lifting with the forklift.

6. In future, when cutting the holes for the vent pipe and toilet seat, ensure the holes are cut as tight as possible to prevent odour escaping and flies entering through the gap.

7. Place the wiring for the LEDs on the outside of the cubicle, never underneath the floor. Many of this formation got covered in black waste and had to be thrown away on packdown.

8. Before construction of each unit, ensure the blockies are screwed in. The nails that they are supplied with the cubicles do not hold.

9. Consider getting new recruits in for Loo Crew for servicing through the event. Perhaps using one existing DPI crew member, per day, per run, just to manage the fresh volunteers.

10. Instigate a rule of if you don’t show up for your toilet shift, or any shift for that matter, you don’t get fed in the crew kitchen. You could easily ensure this happened by issuing meal vouchers only after you do your shift. No meal voucher, no meal.

11. Cut some oval shapes into the sides of each cubicle, along the bottom edge. This would provide a hand hold to lift the completed cubicles up onto the flow bins (IBC’s) a lot easier.

12. Service the high pressure sprayers before use.

13. Allocate one trailer, one flow bin full of water, one pressure sprayer along with all the other smaller equipment to each Loo Crew. Don’t unpack these or use them for other teams. It’s a hard task during event to move heavy equipment around first thing in the morning and find all your equipment before you can even begin to start your run. Maybe even make a parking bay for each crew to leave their gear in safely, where it won’t be moved overnight.

14. Have each team go via the waste station to offload the rubbish after each run so it doesn’t get piled up back at the DPW camp and be at risk of blowing away.

15. DMV, Medics/Sanctuary, OCC and DPW toilets need to be hidden better. Perhaps making a shade cloth surround would work?

16. A forklift driver should be available/on shift each day of event for DPW.

17. Toilets need to be topped up with water more often. A separate run for just filling up would be ideal as the sprayers don’t allow for fast filling of water. Just once, a few days into the event, to ensure no poo piles are happening and to ensure the chemically treated water is covering the poop. This ensures effective odour control and reduces flies. Each 20L of water added should have one sachet of chemical added.

18. Ensure there are enough crew to do a toilet run on the Monday, if we even do a toilet run at all. This was the day a lot of people left site and Collexedus was in full swing. Most of the toilets were clean and had plenty of toilet paper. We only had a few people show up for a toilet shift this day, some crew had already left site, resulting in only a few people doing the entire sites worth of toilets.

19. On that note, make sure the Loo Crew Team Leads are aware of when their crew are leaving site and get more volunteers enlisted to cover the shortfall.